Storage trends and new technology ignite fire risks for commercial warehouses

ArticleJuly 28, 2022

By Joffre Mishall, Head of Property, U.S. National Accounts, Zurich North America

The growing popularity of a “too-tall, too dense” approach to commercial warehouse storage is increasing the size and severity of fires and with it, the risk to lives and property.

Warehouses by their nature are designed to store a large amount of material in a relatively small space. However, companies have been pursuing ways to increase the density of stock in the same amount of space. Factors contributing to this trend include the growing demands of e-commerce and just-in-time deliveries; automated technology that creates efficiencies for identification and retrieval of goods; and the desire to offset rising real estate costs by building up, not out.

Unfortunately, this trend is creating scenarios that set the stage for larger, more destructive fires that exceed the abilities of even the most experienced firefighters. The fact that many warehouses are being built in more rural areas with less sophisticated public fire organizations further complicates this situation.

To demonstrate the size and impact of fires in today’s commercial warehouses, consider these recent examples:

- A 2022 fire in Indiana destroyed a 1.2-million-square-foot fulfillment warehouse for a major retailer. It required 350 firefighters and 30 fire agencies assisting in fighting the blaze. Damage was significant enough to prevent it from reopening.1

- A February 2022 fire in a document storage warehouse in Illinois burned the 250,000-square-foot facility to the ground. It took two days to fully extinguish the fire and, at one point, required so much water fire officials said it started to drain the municipal water supply.2

- In 2021, a fire “the size of a city block” destroyed a California warehouse and created a post-fire field of debris the size of two football fields.3

- A 2021 fire at a 1.2-million-square-foot North Carolina distribution center for a television shopping channel was ranked “the largest structure fire” in the state’s history. It took crews from over dozens of fire departments 10 days to battle.4,5

The total costs of these fires are still being assessed. For some perspective, consider that of the top 10 costliest large-loss fires in the U.S. in 2020, a fire that destroyed a 600,000-square-foot online sales warehouse ranked third, with a loss of $300 million.6 And a massive fire in Andover, England that destroyed a customer fulfillment warehouse cost the Ocado company about $120 million in U.S. dollars.7

These immense fires dramatically underscore the need to address this risk. They pose life-and-death dangers to both the building occupants and firefighters; can result in millions of dollars of losses; and adversely impact the environment, notes the National Fire Protection Association (NFPA).8 To that last point, several of the aforementioned warehouse fires in 2021 and 2022 emitted chemicals into the air and local water systems. What’s more, rising inflation rates further escalate the replacement costs of goods and the buildings that store them.

Storage configurations and technology create new challenges

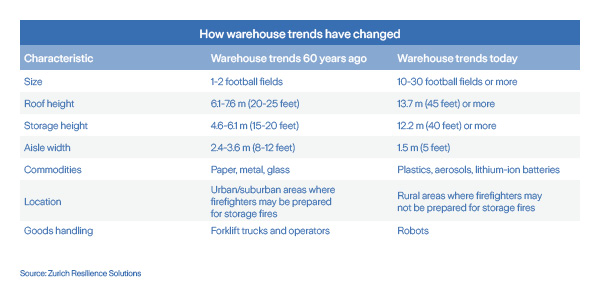

Consider how warehouse trends have changed over the past six decades:

In addition, it’s worth examining two specific trends in commercial distribution warehousing that are complicating fire mitigation:

1. Storage-savvy tech and sprinklers: In the past, warehouses handled goods by the pallet load and stored them in conventional piled or racked configurations. Over the past 50 years, sprinkler guidelines were developed for these conventional configurations and are found today in standards such as NFPA 13, “Standard for the Installation of Sprinkler Systems.”

But the e-commerce warehouse has become an active environment fulfilling orders. That means goods are being handled in smaller amounts, i.e., individual cases or pieces. According to my colleague Richard Gallagher, Risk Engineer and Property Technical Director for Zurich Resilience Solutions, this has given rise to new storage configurations that are not adequately addressed by standards such as NFPA 13.

For example, the protection of racked storage depends on adequately sized and spaced flues to allow a fire’s heat to flow vertically up to sprinklers and sprinkler discharge to flow downward dousing a fire. With palletized goods, adequate flues for the most part were automatic. But with pallets broken down into case goods or individual items, flue spaces tend to be too small, misaligned vertically, or even omitted. As Gallagher noted, “When you block flues and can’t get water into the (storage) rack, you run a higher risk of burning your building down.”

As another example, e-commerce warehouses often store goods in open-top containers to facilitate order picking. Standards such as NFPA 13 offer no protection guidance where open-top containers are used. The challenge here is that open-top containers capture the sprinkler discharge that would otherwise flow downward toward a fire. The outcome is similar to inadequate flues.

In general, the modern e-commerce warehouse needs sprinkler protection beyond NFPA 13 to be considered adequately protected.

2. Storage-savvy tech and firefighting: The pace of play in the e-commerce warehouse is driven by order fulfillment rates, especially where next-day delivery is offered. This drives a need for automatic storage and retrieval systems (ASRS), especially those using robots.

Traditional ASRS warehouses have always been a firefighting challenge. With goods stored 40 or more feet above the floor, firefighters have no realistic means to access fire-damaged goods in the upper storage tiers.

Also, newer robotic ASRS adversely impact firefighter access. Aisles are becoming too narrow or are even being eliminated. Narrow aisles hamper firefighters’ movements when they’re wearing personal protective gear that includes self-contained breathing apparatus. Firefighters may not even be able to turn around in an aisle! And, where aisles are eliminated, firefighters may have to work hours to access fire damaged goods located just 10 or 15 feet from an access point.

Recognizing the realities of extinguishing fires

Although storage trends are changing, the principles of fully extinguishing a fire still rely on two steps: First, sprinklers of adequate design that can control or suppress the storage fire so it does not spread and, second, firefighters who achieve final fire extinguishment.

Step two is crucial. Although sprinkler systems can control or suppress fires, it is the role of firefighters to achieve and confirm final extinguishment. A warehouse fire is not considered fully extinguished until all fire-damaged goods are removed from the building. There’s a reason for that. Even a tiny ember can smolder for hours and reignite a fire, potentially destroying the building.

But getting materials out of a building first depends on firefighters’ ability to access the materials, Gallagher explains. “If goods are stored too high or too densely, firefighters may find it impossible to reach the fire-damaged goods.”

Even if firefighters can reach the goods, consider that they will be wearing heavy equipment, with limited time in their air pack, and working with poor visibility, he notes. “They’re on their hands and knees, dragging a hose, they’ve already crawled 100 feet into the building, and now they’re faced with a ton of material they’ve got to remove.” In short, each warehouse needs a realistic final fire extinguishment plan that stays within the physical limits of human firefighters.

Furthermore, no property is ever worth the loss of life. We never want a firefighter to be harmed protecting property.

When access is impeded, the fire department is often forced to use large hose streams to try and control the fire. One of these hoses can release 500 to 900 gallons of water a minute, and sometimes more, creating even greater water damage to goods.9

Why smoke creates serious risks, too

It’s impossible to discuss fire-related property risks without addressing the adverse and costly impact of smoke. Fire obliterates what it consumes, but it also produces smoke and soot that can travel far beyond the flames. Depending on what has been burned, different types of smoke will result, incurring expensive cleanup costs but also the possibility of rendering impacted materials worthless.

Some points about smoke damage:

- Smoke from a fire will often migrate to the physical boundaries of the building walls.

- Did you know smoke particles ionize and possess electrical charges? Smoke and soot can short-circuit electronics and contaminate HVAC systems.10

- Cleaning up smoke deposits on building features can be very labor intensive and expensive, and should be done by experienced professionals. For example, if bar joists at the roof level need to be cleaned, this may have to be done by hand using mobile equipment. Simply pressure-washing is rarely an option due to equipment, utilities and storage that may be damaged from the water.

- Smoke leaves discoloration and odors in its wake. Smoke can also cause significant damage to stock because of the harmful products of combustion. While some commodities in a warehouse may be easier to clean up either by the nature of the product or how it is packaged, some items may not be salvageable.

Overlooked costs of large warehouse fires

Current economic trends also exacerbate the total cost of these massive fires. While these factors come into play for any commercial warehouse fire, their losses are multiplied when a fire destroys a single, gigantic property filled with goods. Consider:

- The loss of so many goods in one large warehouse puts the supply chain in jeopardy for all of the companies depending on those products. It further aggravates an already compromised global supply chain and contributes to today’s inflationary environment.

- Businesses, in an effort to protect their brand and avoid liability, are less tolerant of selling or salvaging products with any level of smoke damage than they have been in the past. Consequently, it increases the stock damage from smoke and the resultant costs. Even if the damage is limited to packaging, companies are discovering that repacking may be as expensive as the cost of the product. Again, inflation makes replacing products more expensive.

Preventing commercial warehouse fires

Businesses need to take every possible precaution to prevent a storage fire. As discussed here, that includes avoiding the shortcomings of too-tall, too-dense warehousing. The better option is to have several warehouses that are adequately spaced, with storage configurations most likely to remain within the capabilities of your local public fire service and their sprinkler protection designs, and allow adequate aisles and flue spaces.

Here are some additional tips for from the Zurich Resilience Solutions team11:

- Develop a pre-fire plan with your local fire department to help support the most effective response. Like any mitigation plan, this process should be reviewed and updated as necessary, especially if site conditions change.

- The result of the evaluation of the local fire department capabilities and the situation at the site may lead to the assumption that the final extinguishment of the storage is not feasible. In such cases, it may be appropriate to consider the use of internal fire barriers, firewalls and external space separation distances.

- Consult with your fire protection engineer or sprinkler contractor to ensure the automatic sprinkler system can meet the demands of a potential fire within your facility.

- Regularly inspect, test and maintain your storage warehouse’s automatic sprinkler system.

- Assume manual firefighting will be needed. Firefighters are instrumental to achieving final fire extinguishment. The local public fire service needs to review your warehouse and storage areas to familiarize themselves with the storage commodities and configuration. Consider choosing storage configurations within their capabilities, staffing, training, equipment and experience. For example, could a firefighter credibly reach fire-damaged goods at the highest elevations of, or the deepest points within, your storage array?

- Ensure that any robotic or automated stock handling systems will shut down automatically upon fire detection. This includes smoke detection, heat detection and a sprinkler’s water-flow detection.

- Train your staff so they will know which sprinkler control valve to close after a fire. And, whenever sprinklers are shut off, maintain a fire watch posted in the fire area and a valve watch posted at the shut sprinkler valve. The fire watch is to immediately notify the valve watch to open the sprinkler value if there are signs of a rekindling fire.

- Identify sources of water for manual firefighting. The water demands for storage fires can be very high, so it’s important to review the availability of water and conduct regular flow tests to help assure you have sufficient capabilities.

- Develop a plan so fire-damaged goods are never left unsupervised inside a building. This risk-mitigation step anticipates the very real risk of fire-damaged goods reigniting.

- The finding from the evaluation of storage fire protection and final fire extinguishment should be included in the overall hazard analysis of the site as well as the impacts it may have on the business.

Learn more about Zurich’s Property solutions.

Joffre Mishall is Head of Property, U.S. National Accounts, for Zurich North America. Before taking on his current role, he served as Zurich’s Midwest Regional Property Leader, Property Portfolio Manager, Property Domestic Portfolio Manager and Property Claims Large Loss General Adjuster Manager.

References

1. Allen, Jake. “Walmart Fulfillment Center Will Not Reopen After Destruction from Massive Fire in March.” The Indianapolis Star. 25 April 2022.

2. Horng, Eric, et.al. “Bartlett Warehouse Fire at Access Document Storage Facility Continues Burning for 2nd Day.” ABC7 Eyewitness News website ABC7Chicago.com. 4 February 2022.

McAboy, Koco and Kj Hiramoto. “Video: Two Massive Fires Break Out at Warehouses in Carson and El Sereno.” FoxLA.com. 30 September 2021.

Thomas, Aaron. “Fire Officials Declare QVC Plant Fire the 'largest Structure Fire' in History of NC.” WRAL.com. 14 February 2022.

Associated Press. “Fire Damages Huge QVC Distribution Center in North Carolina.” U.S. News & World Report. 18 December 2021.

“Facts + Statistics: Fire.” Insurance Information Institute. 2022.

“Ocado Warehouse Fire: Rebuilt Andover Centre Fully Operational.” BBC.com. 12 August 2021.

“Warehouse Fire Safety.” National Fire Protection Association. November 2020.

Rowett, Jr., Anthony. “From Hoselines to Hydrants: Understanding Water Supply.” Firehouse. 14 November 2017.

10. “How to Get Rid of Smoke Damage After a Fire at Your Business.” Servicemaster Restore. 19 July 2021.

11. “Storage Fires and Final Extinguishment.” Zurich Resilience Solutions. August 2020.

The information in this publication was compiled from sources believed to be reliable and is intended for informational purposes only. All sample policies and procedures herein should serve as a guideline, which you can use to create your own policies and procedures. We trust that you will customize these samples to reflect your own operations and believe that these samples may serve as a helpful platform for this endeavor. Any and all information contained herein is not intended to constitute advice (particularly not legal advice). Accordingly, persons requiring advice should consult independent advisors when developing programs and policies. We do not guarantee the accuracy of this information or any results and further assume no liability in connection with this publication and sample policies and procedures, including any information, methods or safety suggestions contained herein. We undertake no obligation to publicly update or revise any of this information, whether to reflect new information, future developments, events or circumstances or otherwise. Moreover, Zurich reminds you that this cannot be assumed to contain every acceptable safety and compliance procedure or that additional procedures might not be appropriate under the circumstances. The subject matter of this publication is not tied to any specific insurance product nor will adopting these policies and procedures ensure coverage under any insurance policy.